Caseless ammo is the cartridge of the future… and always will be. Okay, that’s a bit of a joke, but it does seem like caseless ammo is just not going to happen.

Caseless ammunition could be the future of ammo, but we’ve historically had difficulty creating a reliable and capable system that eliminates a cartridge’s case.

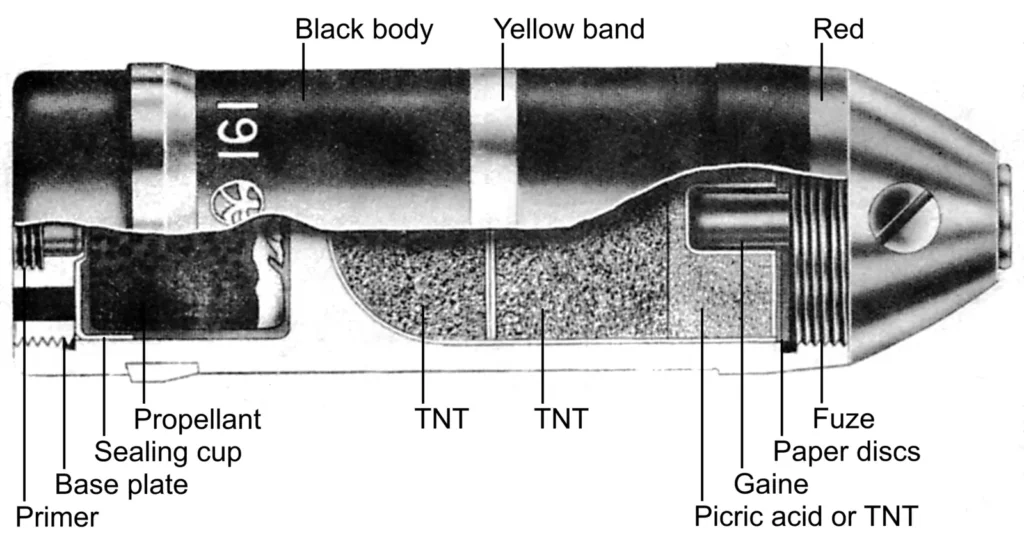

An ammunition cartridge has four main components: the projectile; propellant; primer; and case. The projectile leaves the barrel and hits the target. The propellant, when ignited, turns to gas and propels the projectile. The primer, when struck by the firing pin, ignites the propellant. Finally, the case holds it all together.

The case is often the largest, heaviest portion of the cartridge. Caseless ammo would eliminate the case, benefiting both the end user and the firearm. Various attempts to create caseless ammo have been made dating back a long time.

The first self-contained caseless ammo was developed in the 1850s by prolific inventor Walter Hunt who called his invention the Rocket Ball Cartridge. In an era when muzzle-loading rifles reigned supreme, the Rocket Ball was revolutionary: it was basically a bullet hollowed out and filled with gunpowder and a sealed primer cap.

The Rocket Ball gave birth to lever-action handguns and rifles created by the Volcanic Repeating Arms Company. The ammunition and concept worked – but not well. The bullets were very weak and slow, with very limited range. The Rocket Ball helped propel the popularity of cartridge firearms and prematurely introduced the idea of caseless ammo.

Beyond the Rocket Ball

During World War II, feeling the pressure of wartime logistics – brass, copper, and similar materials were becoming scarce – Germany began researching the idea of caseless ammo for large caliber guns. It made some progress and produced a 55mm aircraft autocannon that uses a mostly caseless round.

The Japanese had better luck with the Ho-301, a 40mm autocannon used near the end of the war.

Daisy, the company behind the BB gun, developed the Daisy V/L, the first production rifle for caseless ammo. This weird gun fired a .22 caliber projectile propelled by a cylinder of propellant with no primer. The rifle used 2,000-degree hot air to ignite the propellant.

In the late 1970s, the Russians developed 40mm internal-propellant caseless grenades for under-barrel grenade launchers. HK developed the G11, a 4.7mm round encased in a brick of explosive. Metal Storm developed unique weapons that employed a caseless idea, but not the traditional variant.

Nevertheless, none of these creations were particularly effective or useful.

Related: How the AR-18 influenced a generation of service rifles

The benefits and downsides of caseless ammo

Caseless ammo reduces weight and, theoretically, bulk for a soldier. The more ammo a soldier carries, the better, so, if we can reduce ammo weight and bulk, we can load soldiers down with more ammo. The rate of fire could also be increased due to less movement required to fire the gun. Further, a lot goes into producing ammunition cases, so if we ditch the case could also produce cheaper ammo.

Additionally, we could produce simpler, more reliable firearms, as we wouldn’t need an extractor, ejector, or even an ejection port. However, you have to answer a simple question: How does the shooter clear malfunctions or the gun as a whole?

Further, ammunition cases eject when fired and the expanding cases seal the chamber. Having no case means no seal, therefore gun designers must be creative with how they seal the chamber. For example, Benelli created a submachine gun that used caseless ammo and designed the bolt and chamber to allow the bolt to be the gas seal.

Besides, questions that would need to be addressed, caseless ammo has many disadvantages under the current technology.

One of the most critical problems is the fragility of the cartridges; they can break, chip, and deform, which creates issues feeding the gun. Some of these ammo types are also sensitive to moisture, which can reduce their reliability.

There are also heat issues: A cartridge case acts as a great heat sink when loaded into a hot chamber. When fired, the case absorbs a lot of the energy produced with the firing cartridge, slowing down how fast the weapon can overheat. However, guns firing caseless ammo can overheat, and you can run into cook-offs. (Regular ammo is susceptible to cook-offs, too, but it takes a lot of shooting to cause that problem.) Caseless ammo would need to be heat-resistant in some form.

We are finally getting to the point where we are experimenting with different case designs, which might lead to caseless technology. I think eventually, we’ll be able to solve the problems with caseless ammo. The benefits are certainly there, and they could be a step towards more futuristic firearms designs.

Feature Image: Caseless ammo in a pack, Lightweight Small Arms Technologies. (Photo by Kori Phillips/U.S. Army Armament Research, Development and Engineering Center)

Read more from Sandboxx News

- A stealth bomber for the toughest missions: The B-2 Spirit

- Navy’s wants to turn its AIM-174B missile into a hypersonic weapons killer

- Operation Midnight Hammer: How American stealth bombers struck Iran’s nuclear facilities

- ‘USS Dorado Project’ aims to solve WWII’s biggest submarine mystery

- Explosive confidence drills against a moving car